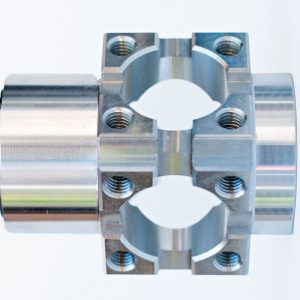

Multi-Axis Machining / Mill Turning

What machining is critical to the forward movement of high precision machining? Multi-axis machining is absolutely the right. Standard three-axis machining has been the tried and true for years, but it can not compare when you need to step up production, especially of any unique configuration, that’s when 4 and 5 axis machining steps in, it will take you into high gear and get productivity and efficiency at their maximum output! While the three axis machines allow for standard movements (up and down, left and right, forward and back), the additional axes create additional movements that smooth out the process for setting up and runtime, thus conserving production expense! With the standard equipment, parts would have to be turned and manipulated to access another side, then the part would have to be setup in the machine with a new program. Multi-axis creates a passage for the part to be moved automatically within the machine as part of the program. The reduction in setup time is incomparable to any other system. And, with the multitude of tooling available in the machines, there is practically no limit to the type of work that can be performed. The opportunities are almost limitless.

Mari Manufacturing’s state of the art multi-axis machinery delivers the utmost efficiency and cost effective products so we can get the most difficult of requests done seamlessly for any industry of our friends in business!